CellCap and cellulose recovery from sewage

The IntenSieve® is a rotating belt finesieve (RBF). The rotating filtermesh removes suspended solids from the sewage and produces thickened screenings. Main part of the screenings at a sewage treatment plant are cellulosic fibers (toilet paper). The screenings might be reused again as raw material. For some applications the quality of the screenings as collected might be suitable for further processing or reuse. But for several more high-value applications, better quality cellulose is desirable.

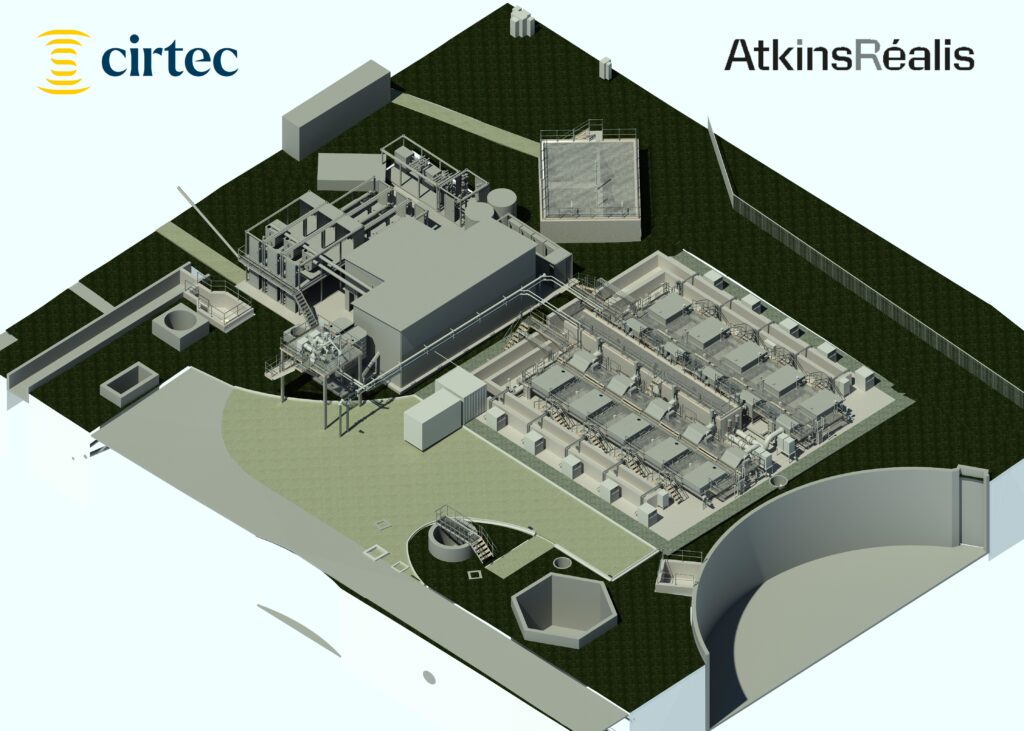

By integrating CellWash® before the IntenSieve®, a two-stage filtration system (CellCap®) is created that not only extracts a highly digestible residual stream but also harvests a clean cellulose stream. This cellulose can be easily processed into a marketable renewable resource. The raw materials present in wastewater can significantly contribute to the transition towards a more circular economy and cellulose is an important renewable raw material for which a market is already developing in large parts of Europe.

Challenge

Reducing Energy and Sludge Load While Advancing Circularity

Implementing CellCap® significantly reduces the load on sewage treatment works (STWs), thereby decreasing energy consumption for aeration and sludge dewatering. By digesting the extracted residual stream, biogas production is maintained, aligning with the goals of Water Utilities to become energy-neutral and more circular.

How does it work?

The process

In the CellCap® concept, a CellWash® is installed for the IntenSieve®. The pre-separation consists of a fine-meshed drum where, through an inventive feed system, the cellulose fibres can escape, where hair, plastics, leaves, seeds, and other components are caught. This residual stream contains a significant organic load, meaning that it can be digested and used for biogas production.

After removing the cellulose fibres, they are dewatered in the CellPress® into a firm solid substance, containing a solids concentration up to 35 or 40%. To optimise the efficiency of the whole CellCap installation, filtrate of CellPress® is brought back to the Inlet of the IntenSieve®.

Discover our solutions

- Municipal

- Industrial

Filter – IntenSieve®

- Wastewater

- Industrial water

- Resource Recovery

The IntenSieve® is a rotating belt finesieve. A compact, chemical-free finesieving solution that removes suspended solids and frees biological capacity.

Our positive impact

The impact on downstream treatment largely matches that of IntenSieve®. However, with cellulose a limited proportion of digestible carbon is removed, producing slightly less biogas. Instead, a more sustainable raw material does become available (reuse is two steps higher on the sustainability ladder than conversion to energy). However, cellulose can be dewatered further than sludge (up to about 38% Ds) and do so without adding chemicals, keeping the energy balance almost balanced.

Sewage is a faecal-contaminated source that can contain additional pollutants depending on the industries discharging into the sewage system. Therefore, any material extracted from sewage is initially considered waste and cannot be sold without proper treatment. CirTec, in collaboration with its partners Cellvation and Recell Group, has developed a process to upgrade the extracted and dewatered cellulose into a sellable safe intermediate product.

In this process, the dewatered cellulose stream is dried and sanitized. Bacteria and viruses are eliminated, and pathogens are inactivated, ensuring the safety and quality of the final product called Recell®. This innovative approach not only supports the circular economy but also aligns with regulatory requirements for safe and sustainable waste management.

It is crucial to emphasize that the reuse of recovered resources must never pose new risks to the ecosystem or to human and animal health. Our process ensures that the upgraded cellulose meets stringent safety standards, providing a reliable and environmentally friendly solution.