Your challenges

Presence of H2S in biogas

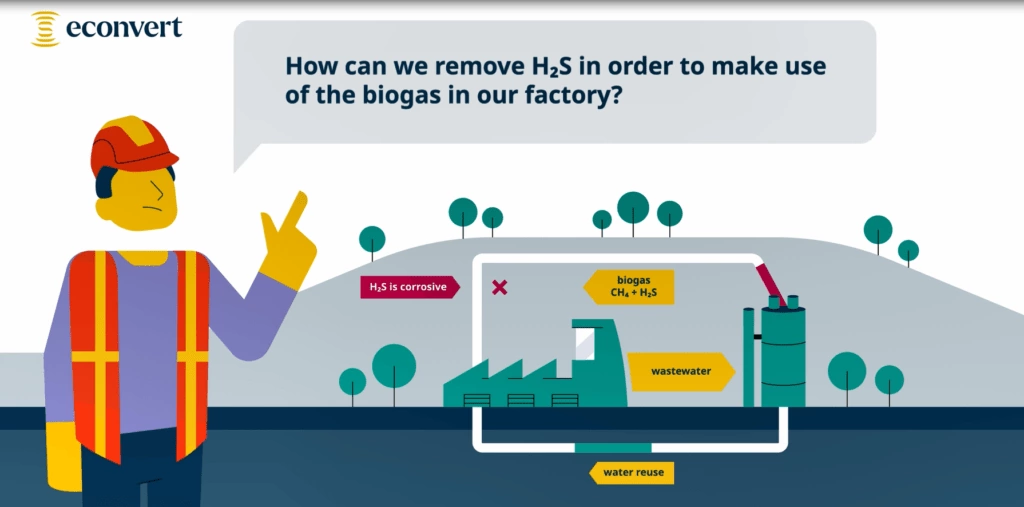

H2S is a component in biogas that requires treatment, before the biogas can be utilized as an energy source. Econvert-RTF® achieves a 99% H2S removal rate, and allows the biogas to be re-used directly or with additional polishing with activated carbon filters depending on end-user needs.

Sustainability and carbon footprint goals

There is pressure for companies to become more sustainable and to achieve certain sustainability goals. Econvert-RTF® ensures that energy recovered is not only renewable but also enables to burn the biogas in a correct way without harmful sulfur emissions.

Rising energy costs

Energy costs are continuously increasing, and there is pressure to adopt renewable energy. Econvert-RTF® treats biogas and ensures the biogas has the right quality, pressure and humidity for re-use. The reliable performance and non-clogging set-up enables a high uptime and high energy recovery availability.

Want to know how our innovative wastewater treatment and biogas desulfurization solutions can benefit your business?

The process

The Econvert-RTF® is a regenerative trickling filter designed for biogas desulfurization. It consists of a filter bed in which hydrogen sulfide is removed from the biogas through biological oxidation. Depending on the selected process conditions, the system can be steered towards either elemental sulfur or sulfuric acid production. The key innovation of Econvert-RTF® is its ability to regenerate (i.e. ‘wash’) the filter bed material. Regular decommissioning of the desulfurization installation to clean the filter bed is no longer necessary, since solids accumulation is prevented by automatic recirculation of the filter bed material. Aerobic effluent can be reused as suppletion water (if available), minimizing (potable) water consumption.

Our positive impact

The reliable biological solution without chemicals

>99% H2S removal efficiency

H2S removal rates of over 99% can be achieved. Due to the high H2S removal rates, the biogas can be reused directly or only needs minor additional polishing with activated carbon filters depending on end-user requirements.

Low operational costs

Due to the regeneration of the alkalinity in the bioreactor the operational costs are low. Compared to chemical systems where no alkalinity is regenerated, the amount of caustic consumption can be up to 20 times less.

No clogging

Clogging in the Econvert-RTF® is prevented by its built-in cleaning system. During operation the installation can be put in cleaning mode without any negative effects on the ongoing biogas treatment.

Continuous operation

Econvert-RTF® can be operated continuously, without regular time-consuming and extensive maintenance work.

Contact our experts

Other solutions

- Municipal

- Industrial

Anaerobic – Econvert-Dsulph®

- Resource Recovery

- Industrial water

- Sludge

- Wastewater

Econvert-Dsulph® is a proven, high-efficiency biogas desulfurization solution that combines the chemical absorption of hydrogen sulfide (H2S) in the scrubber with the biological (...)

- Industrial

Anaerobic – Econvert-UASB®

- Wastewater

- Industrial water

The Econvert-UASB® (Upflow Anaerobic Sludge Blanket) has a proven track record for decades. Its robust and reliable configuration enables the handling of large varieties of wastewater (...)

- Industrial

Anaerobic – Econvert-EGSB®

- Wastewater

Econvert-EGSB® (Expanded Granular Sludge Bed) is the optimal solution after decades of experience, development and optimization. Combining a small footprint with robust internals (...)

- Municipal

- Industrial

Anaerobic – Econvert-IR®

- Wastewater

- Industrial water

The Econvert-IR® (Internal Recirculation) is designed to create the ideal process conditions – even under extreme conditions. Thanks to its unique two-stage settling system, (...)

- Industrial

Anaerobic – Econvert Anaerobic Rental

- Wastewater

- Industrial water

- Resource Recovery

We understand that CAPEX is not always readily available to invest in anaerobic wastewater treatment, or that you may want to avoid long-term financial commitments. At Econvert, (...)

- Industrial

Anaerobic – Econvert-DGF®

- Resource Recovery

- Industrial water

- Wastewater

The Econvert-DGF® (Dissolved Gas Flotation) is an anaerobic solution developed to treat raw wastewater with high concentrations of total suspended solids (TSS) and fats, oils, (...)

- Industrial

Services: Anaerobic wastewater treatment & biogas

- Wastewater

- Resource Recovery

In the end, it’s not just the equipment that treats your wastewater, it’s the whole process. At Econvert, part of Nijhuis Saur Industries, we offer various anaerobic wastewater (...)