Our story

Founded in 2010 with a clear purpose — to recover value from wastewater and enabling a circular society — CirTec has always believed that water and resources deserve more than a single use. Since joining Nijhuis Saur Industries, we have strengthened this purpose as part of #MissionWater: advocating for water, closing loops, and ensuring water receives the value it deserves.

We operate with a long-term mindset, supporting customers from initial ideas and piloting through full-scale realization, commissioning, and operational support. Whether we work directly with end-users or alongside engineering partners, we stay close to our clients to understand their challenges and design solutions that truly make an impact.

Today, CirTec is a trusted global technology center within NSI, recognized for game-changing innovations in circular water treatment and resource recovery.

Key figures

26%

Of Europe’s phosphate requirement can be covered by phosphate recovered from sewage

2 tonnes CO₂

Saved for every tonne of industrial fibre applied

10 million trees

Used every year for toilet paper worldwide – Cirtec helps drastically reduce this

"The transition to a circular and sustainable society is not a goal but an absolute must. "

Our industry applications

We support a broad range of industries and utilities, designing and implementing systems for:

-

Sewage treatment

-

Meat & fish processing

-

Food processing, beverage & Dairy

-

Pulp & paper

-

Textile

-

Biosolids and sludge processing

-

Resource recovery (water, nutrients, cellulose, fibers, energy)

Our solutions help modernize existing installations, relieve capacity pressure, improve performance, and support circularity and compliance targets.

Our solutions

CirTec combines engineering, equipment supply, piloting, commissioning, and long-term service to deliver reliable, scalable and circular water solutions. From standalone units to full EPC execution, we support clients throughout the entire lifecycle of their installation.

Sludge treatment: Belt press & belt thickener

Advanced technologies to separate or thicken solids, increasing efficiency, reducing sludge volume and improving downstream performance.

Belt press

Belt thickener

Finesieve solutions

Design and implementation of treatment steps that remove solids, organics and nutrients using efficient mechanical and biological processes.

Tertiary treatment: Disc filter

Solutions that minimize sludge production, stabilize biosolids and prepare them for reuse, energy recovery or safe disposal.

Cellulose recovery

By combining an advanced filtration system with a pre-washing step, we recover not only an energy-rich sludge but also clean cellulose that can easily be used in circular applications.

All NSI solutions

NSI provides a unique portfolio of smart game-changing solutions in sustainable water use, energy and resource recovery combined with our services for a sustainable and resilient future. Nijhuis Saur Industries has broad experience and application know-how within a wide range of industries, designing the most appropriate solutions.

Discover all our solutions: https://www.nijhuissaurindustries.com/solutions/

Circular expertise & added value services

Resource recovery is at the heart of CirTec’s mission. We develop technologies that extract valuable materials directly from wastewater and sewer networks, including:

• Reusable water

• Nutrients (nitrogen- and phosphorus-rich streams)

• Cellulose fibers (from toilet paper)

• Low-grade energy and heat

Helping your through every stage of the project

We provide complete project delivery — including design, engineering, manufacturing, installation and commissioning — ensuring reliable and efficient turnkey treatment systems tailored to customer needs. And with our Pilot Testing, each CirTec system can be tested in pilot form prior to full-scale implementation to ensure suitability and optimal performance under real-world conditions.

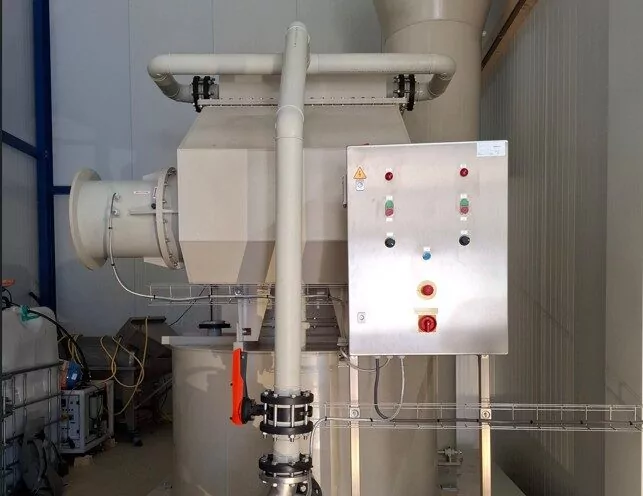

Finescreen solution for sewage treatment plant

Cellulose recovery key figures

3.3 million tonnes

Cellulose can be recovered annually from sewage in Western Europe

8.25 million tonnes

CO₂ equivalent saved through cellulose recovery

253,000 tonnes

Chlorine saved by using recovered cellulose

1.8 billion m³

Water saved during the production of recovered cellulose

Reference examples

- Municipal

- Municipal wastewater

Decentralized sewage treatment plant Oosterwold

The Oosterwold district in Almere is a unique residential area where sustainability, self-sufficiency and innovation are central design principles. To support this vision, a decentralised sewage treatment plant was developed to serve approximately 800 households. The challenge was to create a compact, future-proof system that not only treats wastewater safely, but also recovers valuable resources and removes micro-pollutants such as pharmaceutical residues.

In a consortium with Royal Oosterhof Holman (main contractor), Akanova and Van Remmen UV Technology, CirTec played a key role in delivering an innovative solution. The system had to perform reliably under fluctuating influent conditions while meeting strict environmental and water quality requirements. The municipality of Almere deliberately chose an unconventional approach, pushing technological boundaries to realise a sustainable, circular water treatment concept.

- Industrial

- Fish processing

Searious Fish Leather Tanning Project

Project’s context & challenges

Searious BV, based in Beetgumermolen, Netherlands, developed a sustainable tanning process to convert fish skin into exotic leather without using harmful substances like chromium, brine, or fungicides. To close the loop in this innovative process, CirTec from Purmerend provided a key water treatment component. The challenge was to treat a liquid stream with high water content and transform it into a reusable, resource-rich concentrate using low-grade energy. This collaboration supports Europe’s circularity goals by turning a by-product of fish processing into a high-value product without generating waste. The collaboration agreement signed at Aqua Nederland trade show.

- Municipal wastewater

Expansion sewage treatment plant Beemster

Municipal sewage treatment plants across Europe are increasingly under pressure due to rapid urbanization and population growth. WWTP Beemster, located in the heart of a protected UNESCO area, faced significant operational challenges as existing infrastructure was pushed to the limits of its design capacity. Conventional solutions such as expanding biological treatment or installing Primary Settling Tanks (PSTs) were impractical due to high costs, long construction timelines, and severe space limitations.

The challenge was to implement a cost-effective, space-efficient, and easy-to-integrate solution that would reduce operational strain, improve compliance with discharge standards, and future-proof the plant for growing loads—all without major civil works.

Wastewater treatment for shrimp peeling operations

Shrimp peeling operations generate wastewater with high concentrations of suspended solids and organic load. If not treated effectively, this wastewater can place significant pressure on downstream treatment processes and pose a risk to surface water quality.

A shrimp processing company faced the challenge of achieving strict discharge compliance while maintaining a reliable, low-maintenance treatment process. The solution needed to be compact, energy-efficient, and capable of removing fine particles and organic matter without complex operation or high operational costs.

Certifications

Management System Certifications

- ISO 9001:2015 (Quality Management System)

Certified by TÜV NORD Nederland, this standard confirms that CirTec’s management system meets international requirements for quality. The scope covers the design, sale, production, and maintenance of machines, as well as the execution of projects in the field of industrial and municipal (waste)water treatment and sludge treatment. The certification is subject to annual evaluation, ensuring continuous improvement and compliance. -

SCC (VCA*) 2017/6.0 (Safety, Health, and Environment Checklist for Contractors)**

Also certified by TÜV NORD Nederland, this certificate demonstrates CirTec’s dedication to safety and health in the workplace. It applies to the execution of projects in industrial and municipal water treatment, including wastewater, drinking water, process water, and sludge handling. Annual audits guarantee ongoing adherence to the highest safety standards.

Contact our experts

General contact

Nijverheidsweg 26

1442 LD

Purmerend

The Netherlands