Your challenges

Handling fluctuating flows and different water types with traditional DAF systems

There’s a need for a solution that is reliable, adaptable, and effective for different water and effluent applications.

Achieving high effluent quality while maintaining a small footprint

Requires advanced skimming and separation technologies that offer stable and efficient performance.

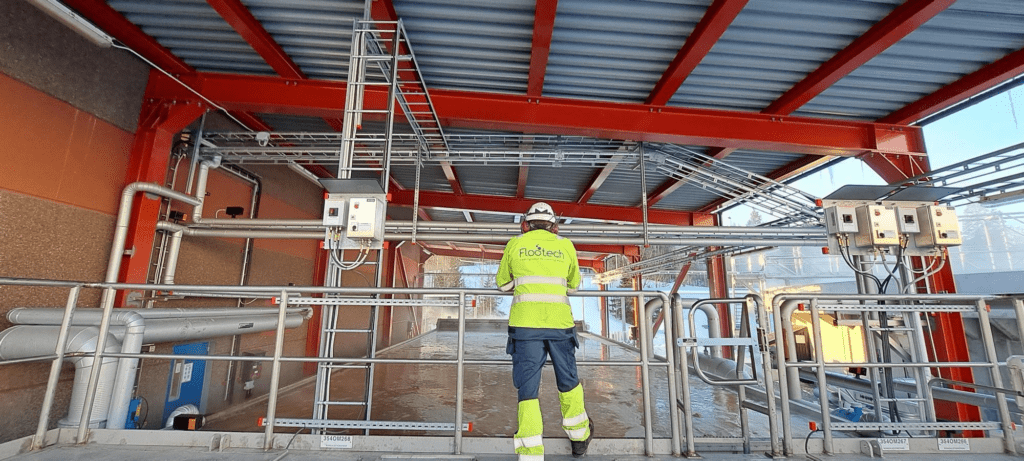

Limitation in facilities with restricted floor space or where compact system integration is critical

Single-level construction offers a small footprint and lower space requirement. No complex concrete foundations, no service platform required and can be installed in spaces with low ceiling height.

How does it work ?

The FlooDaf® Microflotation is a dissolved air flotation system designed to efficiently separate substances and enabling water and wastewater treatment and reuse. Its main features are its rectangular shape, low water depth (1m), automatic dispersion water and basin level control, enabling high hydraulic loadings, small footprint and minimal construction costs combined with a high treatment efficiency and low maintenance requirements.

Process

- Fixative and flocculant are dosed proportionally to the flow rate to enhance flocculation, causing fine particles to agglomerate into larger, more separable flocs. Dosing is controlled automatically to ensure optimal treatment performance and cost efficiency.

- Typically, only 5-15% of the clarified water is recycled to produce dispersion water. In a pressurized tank, this water is saturated with air and introduced via a dispersion nozzle that creates fine droplets, enhancing air solubility. The resulting dispersion water is evenly distributed across the flotation basin through a manifold system.

- When mixed with the flocculated feed water, microbubbles attach to the solid particles, forming buoyant agglomerates that rise to the surface. These are removed by a continuous surface scraping system.

- Clarified water flows beneath the sludge layer and over a guide plate into a clear water chamber. Part of this flow is reused in the dispersion system, while the majority is discharged as treated effluent.

Applications

The FlooDaf® Microflotation is a versatile flotation solution used in a variety of water and wastewater treatment applications, providing reliable performance in different operational environments.

- Industrial Wastewater Treatment: Enhancing primary, secondary, and tertiary treatment processes by removing fats, oils, grease, suspended solids and colloidal materials improving overall plant efficiency. Commonly used in industries such as pulp and paper, food and beverage, energy, where high concentrations of organic matter and suspended solids require effective separation.

- Industrial Process Water Treatment and Recycling: Optimizing water management by separating substances from processes and enabling process water recycling. For example, in the pulp and paper industry FlooDaf® can be applied as a paper machine save-all to remove fibers from white water so the clarified water and fibers can be reused in the paper making process.

- Municipal Wastewater Treatment: Enhancing primary, secondary, and tertiary treatment processes by removing suspended solids and improving overall plant efficiency and effluent quality.

- Drinking Water Production: Removing suspended solids, algae, and organic matter from raw water sources such as rivers, lakes, and reservoirs.

- Sludge Thickening: Concentrating sludge solids before further treatment or disposal, reducing sludge handling costs and improving process efficiency.

Our positive impact

Learn more

Reduced CAPEX

Applicable to large-scale water and wastewater treatment plants. FlooDaf® can be part of a total solution to maximize treatment performance and system procurement.

Reduced OPEX

Excellent tolerance for hydraulic and solid variations, while maintaining a great separation efficiency over a large particle range combined with non-clogging dispersion water system and low chemical needs ensures low maintenance requirements and energy consumption.

Reduced Energy consumption

Over 50% compared to typical dissolved air filtration solutions.

Reduced System Footprint

Single-level construction offers a small footprint and lower space requirement. No complex concrete foundations, no service platform required and can be installed in spaces with low ceiling height.

Enhanced Sludge Removal

The unique 2-wheel skimmer system ensures efficient and gentle removal of flotation sludge, improving sludge handling and effluent quality.

Key figures

Over 3000 m³/h

Per prefabricated single unit

for various water or effluent treatment applications

Applicable to large-scale

over 700 installations worldwide

Proven performance

"FlooDaf® Microflotation can be applied for various water or effluent treatment applications to find economical, efficient and ecological solutions "

Contact our experts

Frequently asked questions

FlooDaf® is typically used in a wide range of applications including raw water treatment, effluent treatment and pulp & paper recirculation streams (e.g., save-all application). An extensive list of references and details are available upon request.

The FlooDaf® is available for a wide range of flows (2.5-2500 m3/h per unit, larger flows with parallel units). This means there are solutions available for very small waste stream applications as well as large water and wastewater treatment needs.

FlooDaf® comes in different sizes and shapes with skid-mounted equipment (for small flows and minimal footprint applications), full size steel basin model (most common) as well as large scale concrete basin models available. Different materials are available depending on process demands (for basin e.g., concrete, stainless, austenitic and duplex).