Your challenges

Many water and wastewater systems face persistent performance issues that go unnoticed due to limited visibility and outdated tools. Without accurate data and targeted insights, opportunities for energy savings, reliability improvements, and operational efficiency are often missed.

Inefficient energy use

Many water and wastewater systems operate without visibility into real-time performance, causing pumps and blowers to run inefficiently and consume excessive energy.

Lack of actionable data

Data may exist in SCADA systems but is often underutilized or fragmented, making it difficult to identify trends or justify operational decisions.

Limited optimization capabilities

Without a specialized platform, continuous energy and cost optimization across complex systems is hard to implement and maintain.

How does it work ?

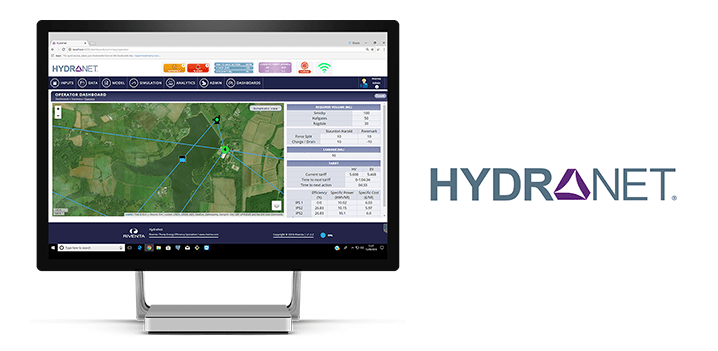

Hydranet connects to existing data sources (e.g., SCADA) and, if needed, uses additional high-accuracy sensors to fill critical data gaps. Every 15 minutes, it recalculates the optimal operation of pumps, blowers, and other assets using a hybrid of AI and deterministic algorithms. The system provides dashboards, performance metrics, and optimization recommendations through an intuitive interface—supporting both short-term actions and long-term planning.

Our impact

Energy Savings

Hydranet continuously identifies inefficiencies in system operation, allowing adjustments that typically reduce energy consumption by 10–40%.

Improved Operational Insight

Operators gain real-time visibility into equipment performance, efficiency, and trends—supporting faster, more confident decision-making.

Extended Asset Life

By running assets closer to their optimal operating range, mechanical stress is reduced, leading to longer equipment lifespan and fewer breakdowns.

Scalable and Site-Aware

Whether applied to a single pump station or a full network, Hydranet adapts to site-specific conditions, asset types, and operational constraints.

We install pressure transducers and temperature probes, edge hardware, and comms systems to gather real-time data, analyzed through our Hydranet platform. This enables optimized efficiency, reduced waste, and lower costs.

Discover Hydranet and:

- Model your pumping systems, reservoirs, and flow control valves to create a network schematic that accurately represents flow paths.

- Optimize target flow rates and select the most efficient run patterns to achieve peak performance.

- Generate detailed reports with real cost estimates by inputting tariffs and viewing specific costs across the network.

The process

1. Data Review or Audit

SCADA data is analyzed, or sensors are installed for high-accuracy measurements.

2. System Configuration

Hydranet is configured to reflect the asset layout and process constraints.

3. Go Live

Real-time optimization begins. Results are tracked every 15 minutes, and performance dashboards are made available.

4. Ongoing Support

Reports, alerts, and recommendations are provided continuously. Field services are available for further support.

Direct Thermodynamic Measurement Technique

The Direct Thermodynamic Measurement Technique accurately measures pump efficiency using only pressure and temperature, making it more reliable than conventional methods, which require flow rate and motor efficiency estimates. It complies with ISO and IEC standards and performs well even in installations with limited straight pipe sections, which are often a challenge for other techniques. The method uses advanced thermometers with high precision, ensuring accurate results.

Unlike Motor Current Signature Analysis (MCSA), which can produce large errors—such as reporting 30% efficiency when the actual value is 75%—this thermodynamic method provides direct and dependable measurements. It overcomes the limitations of other approaches by focusing on fundamental physical properties, delivering precise and trustworthy efficiency data.

Our Team

- Lean, cross-trained team – Each team member is skilled across multiple technical areas, enabling agile collaboration, faster project execution, and reduced reliance on individual expertise.

- Consistent delivery – ISO-certified processes and structured knowledge sharing ensure high-quality outcomes and seamless continuity, even during staff transitions or scaling.

- Rapid results – With streamlined workflows and powerful digital tools, the team can deploy solutions quickly and start delivering measurable value within just a few days.

- Scalable expertise – The team’s flexible structure and proven methodologies allow them to efficiently manage projects of any size or complexity across diverse sectors.

- Sustainable operations – Ongoing internal training and robust support systems guarantee long-term reliability and consistent service for clients with extended or repeat contracts.

Key figures

Up to 40%

energy savings

Over 80

systems optimized globally

15-minute

recalculation intervals

"Hydranet turns raw data into clear actions—supporting operational efficiency and informed planning every day. "

Contact our experts

Frequently asked questions

Yes, it integrates easily with both legacy and modern systems, using existing data where possible.

Hydranet supports pumps, blowers, fans, and other energy-intensive components across water and wastewater systems.

If data gaps exist, Riventa offers high-accuracy sensor installation to ensure complete and reliable inputs.

Yes. Hydranet supports detailed reporting, audit documentation, and continuous performance tracking—all from the same platform.

Hydranet can be operational within a day, depending on the system and data availability.

Yes, it’s designed for both one-time audits and continuous daily optimization, with remote support and updates included.