Your challenge

High ammonia content in wastewater

Reducing and recovery of nitrogen by the ByoFlex®. Reducing the ammonia level as a first step in an end-of-pipe treatment solution.

Fluctuating ammonia loads

The ByoFlex® installation can be operated as a start-stop installation. Direct after a (maintenance) stop the installation is ready to operate. During low- or high loads the installation can be used to the desired capacity.

High N20 emissions

The ByoFlex® installation has no laughing gas emissions during the stripping process. No emissions of environmentally harmful gasses.

High ammonia level in the digester

Reducing and recovery of nitrogen with the ByoFlex®, therewith controlling the ammonia level in your digester for optimal gas production.

Do you want to know more about the ByoFlex®?

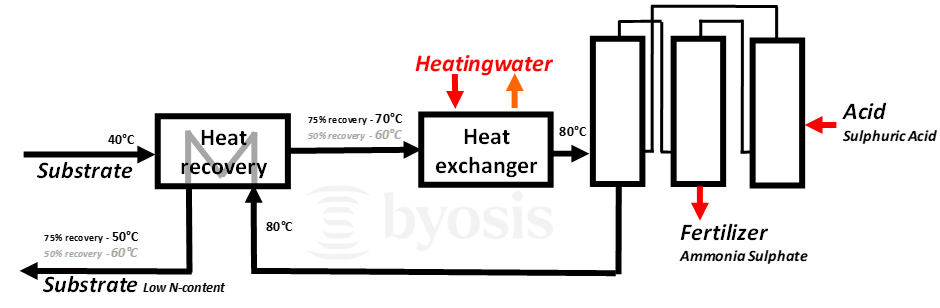

The process

Digestate is pumped via a heating step (tube-in-tube) to the stripper column, where it flows from the top to the bottom. Air is blown through the stripper from the bottom to the top (in countercurrent modus) and ammonia is stripped out of the liquid to the air and absorbed in a single or two-stage washing step with an acid where an ammonium salt solution is formed (typically ammonium sulphate, but ammonium nitrate or citrate is also possible). The washed air is clean from ammonia and re-used in the stripper. A recirculation fan takes care of the air transport. Only a small bleed stream prevents the build-up of undesired components and typically is sent to an odor control unit. The special design of the internals in the system increases the surface area inside the stripper maximizing the efficiency (up to 90%). An alkaline agent is not necessary for most applications. The substrate leaving the system, and low in ammonia, is almost at identical temperature as the incoming substrate enabling a sizeable heat recovery (up to 90%).

Our positive impact

Modular design

The ByoFlex® comes in different sizes: either in a single unit or by combining multiple units. We can design the solution according to your needs. Expansion later on is also easy due to the modular character.

Robust, compact, reliable

Complete with advanced control system, compatible with overall plant control/SCADA systems and ‘plug and play’ for quick erection, reliable operation and 24/7 monitoring.

No risk of clogging and scaling

Due to its unique design there is no risk of clogging and (severe) scaling inside ByoFlex®, enabling a robust and continuous use for substrates high in suspended and dissolved solids.

Low OPEX costs

No caustic is necessary for a stripping efficiency even up to 90%, depending on the substrate viscosity and alkalinity. Energy efficient both in electrical energy and thermal energy by heat recovery.

Key figures

5 m³/h

small/rental ByoFlex

10 m³/h

medium ByoFlex

20 m³/h

large ByoFlex

20 - >100 m³/h

combined ByoFlex

ByoFlex® Mobile Ammonia Stripper

The ByoFlex® mobile ammonia stripper recovers ammonia from highly contaminated substrates, like industrial/municipal wastewater or digestate from foodwaste/agricultural/WWTP-sludge digesters.

ByoFlex® mobile ammonia stripper is directly available, easily transportable (2 trucks) and ready to operate within 2 days after delivery on site. Byosis engineers will train the local operators and during the demonstration-rental period continuous online monitoring- and process advice is available.

A flexible mobile unit to be used as:

- DEMO: To demonstrate and try the ByoFlex® technology.

- RENTAL: Temporary, longer term. Resulting in immediate CAPEX + OPEX savings.

- BUY: Rental + buy option.

Contact our experts

Frequently asked questions (FAQ)

Although it is possible, the best stripping efficiency is depending on cost prize (CAPEX) and operational costs (OPEX). This is often determined by the costs for the stripping process itself and upstream or downstream equipment.

The smallest ByoFlex® we commercially build is for a maximum throughput of 5 m³/hr. Reducing the size does not decrease CAPEX a lot. Our focus is on TOTEX cost over the lifecycle of a product.

If this is the main driver, then the answer is: unfortunately not. Although sometimes you can earn money with the fertilizer in most cases, the business case is driven by other factors like savings in a waste water treatment process, or in waste digester operations.

Heat recovery is done in the same heat exchanger (tube-in-tube) as is used to heat up the substrates. Recovery values as high as 90% are possible. Direct heat recovery is limited by the viscosity of the medium and the particle size of the solids. If direct heat recovery is not possible indirect heat recovery (with water as intermediate loop) is always an option. Or recovery against another liquid stream. In most cases there is an economic optimum.

Cleaning of the stripper is rare and labor extensive. We offer automatic tools for parts that often require cleaning like heat exchangers and demisters. The heat exchanger can be subject to struvite or calcite buildup. Also depending on the substrate. Cleaning can be done mechanically or inline. Byosis offers CIP systems (clean-in-place) for (semi)-automatic cleaning. Demisters can show build up of organic particles and an automatic water wash is offered as optional equipment.

Other solutions

- Industrial

Pasteurization – ByoPast®

- Resource Recovery

- Sludge

- Wastewater

- Industrial water

- Process water

To allow digestate produced from food- or animal by-products to be used or sold as a fertilizer and soil improver according to environmental legislation, pasteurization is needed. (...)

- Municipal

- Industrial

Byosis Services

- Resource Recovery

- Industrial water

- Sludge

- Process water

- Wastewater

At Byosis, part of Nijhuis Saur Industries, we offer a Service Level Agreement which helps you achieve optimal performance and reliability of your ByoFlex® and/or ByoPast® installation. (...)