Project's context & challenges

Severn Trent Water launched the Witches Oak project as part of its Green Recovery Programme to secure additional water supply from Witches Oak gravel lakes and the River Trent. The site’s water required enhanced treatment methods to meet stringent drinking water standards.

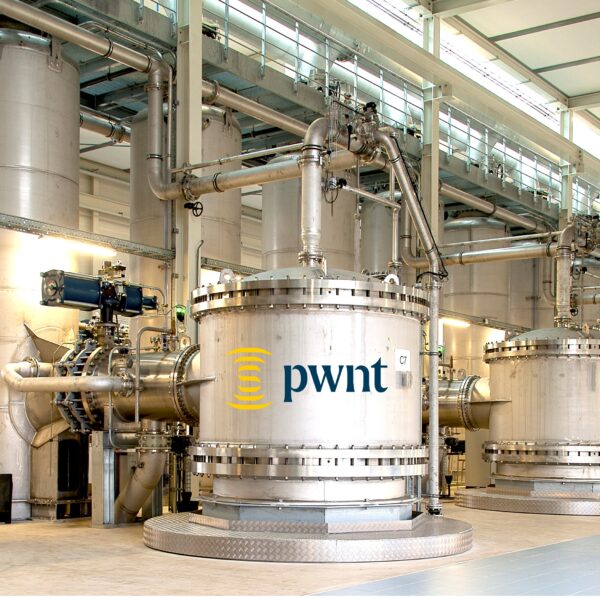

An 18-month pilot phase, featuring PWNT’s ILCA® and CeraMac® technologies, was conducted at Church Wilne WTW to validate treatment performance under variable raw water conditions, including emerging contaminants. The full-scale plant, with a capacity of 89 MLD, is currently being commissioned.

Pilot operations remain ongoing to evaluate additional treatment parameters, both for the ILCA®/CeraMac® combination, and for the potential future integration of PWNT’s SIX® (Suspended Ion Exchange) technology.

Key challenges addressed by the upgrade included:

-

Improving the removal of microbiological and chemical risks, including Cryptosporidium, turbidity events, organic contaminants and nitrates.

-

Enhancing resilience to seasonal variations in water quality by treating a blend of rivers Trent and Derwent.

-

Meeting sustainability and energy efficiency goals by minimizing reliance on chemical and carbon-intensive treatment processes.

Key figures

3

ILCA® ATM

14

CeraMac® C90

89 MLD

23 MGD | 3708 m³/hour

Customer benefits

Enhanced Water Quality & Public Health Protection

The integration of ILCA® and CeraMac® ensures consistent removal of turbidity, Cryptosporidium, Giardia and emerging contaminants, strengthening Severn Trent Water’s commitment to delivering high-quality drinking water.

Sustainable & Resilient Design

By combining biological pretreatment (wetlands), ceramic membranes, and low-chemical treatment processes, the plant aligns with sustainability goals, minimising chemical dependency, reducing waste, and improving operational resilience to seasonal water quality changes.

Long-Term Operational Efficiency

CeraMac® ceramic membranes offer high-flux, energy-efficient microfiltration with low fouling, automated cleaning, and minimal maintenance, delivering reduced operational costs and enhanced asset longevity, with a lifespan exceeding 25 years.

Modular Scalability & Future Readiness

The modular configuration of ILCA® and CeraMac® units allows for streamlined installation, future expansion, and adaptability to evolving treatment requirements, including ongoing pilot investigations for incorporating SIX® (Suspended Ion Exchange).

Solution

The Witches Oak WTW features an integrated treatment approach combining natural, mechanical, and advanced membrane technologies. Raw water from the River Trent and Witches Oak lakes first passes through constructed wetlands, providing a sustainable biological pretreatment step that reduces organics and particulates. PWNT’s ILCA® (In-Line Coagulation and Adsorption) and CeraMac® ceramic membrane filtration systems form the core of the new treatment train, delivering reliable removal of turbidity, pathogens (including Cryptosporidium), and emerging contaminants. Downstream of the membranes, water is further treated through granular activated carbon (GAC) filtration and ultraviolet (UV) disinfection, completing a robust multi-barrier system designed to meet the UK’s stringent drinking water standards.

Technologies Deployed

-

3 × Atmospheric ILCA® (In-Line Coagulation and Adsorption) units

-

14 × CeraMac® C90 ceramic membrane vessels

PWNT Scope of Work

-

Basic and detailed process design

-

Supply, delivery, and inspection of key equipment

-

Ceramic membrane installation

-

Commissioning and start-up of membrane system

Contact our experts

Discover our solutions

- Municipal

Flocculation-coagulation – ILCA®

- Drinking water

In-Line Coagulation and Adsorption ILCA® is a compact in-line coagulation and adsorption process developed by PWNT to simplify and optimise pre-treatment upstream of advanced (...)

Membrane – CeraMac®

- Drinking water

CeraMac® is an innovative and cost-effective ceramic membrane filtration solution, designed to provide high-performance, sustainability, and robustness to water treatment processes. (...)