Project’s context & challenges

Searious BV, based in Beetgumermolen, Netherlands, developed a sustainable tanning process to convert fish skin into exotic leather without using harmful substances like chromium, brine, or fungicides. To close the loop in this innovative process, CirTec from Purmerend provided a key water treatment component. The challenge was to treat a liquid stream with high water content and transform it into a reusable, resource-rich concentrate using low-grade energy. This collaboration supports Europe’s circularity goals by turning a by-product of fish processing into a high-value product without generating waste. The collaboration agreement signed at Aqua Nederland trade show.

Converts fish skin into high-value leather without harmful chemicals

Closes the water loop with integrated treatment and reuse

Reduces environmental impact and aligns with EU circularity goals

Technically and financially feasible solution

Modular and scalable system for future expansion

Solution

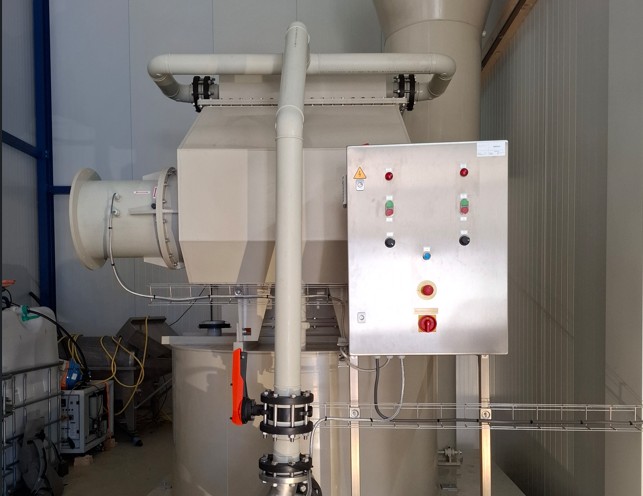

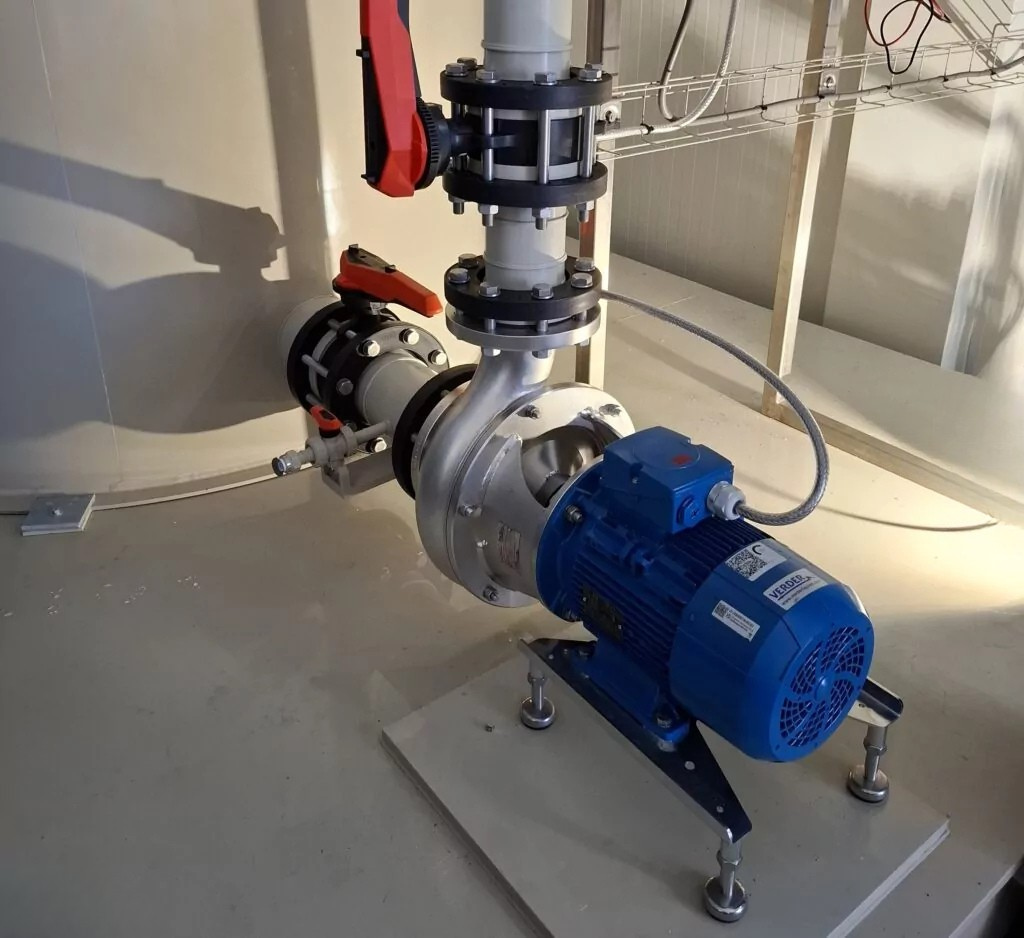

Searious developed a chromium-free tanning process for fish leather, while CirTec contributed a water treatment system that uses low-grade energy to evaporate excess water. This results in a concentrated, reusable stream with positive value. The prototype plant in Leeuwarden integrates all process steps at representative scale. The system is modular and containerized, enabling rapid deployment and scalability. The project demonstrates how circular technology can transform waste into value

Scope of supply

- Design and construction of prototype tanning and water treatment plant

- Integration of evaporation and water reuse technologies

- Modular, containerized system for easy deployment

Applied Solutions

- Chromium-free fish leather tanning process

- Low-grade energy evaporation for water concentration

- Closed-loop water treatment system

- Modular and scalable design for circular production