Project’s context & challenges

Commissioned by South West Water and officially opened in 2020, the Mayflower Water Treatment Works replaces the aging Crownhill plant in Plymouth. Serving about 250,000 residents , it meets increased urban demand and tightens regulation.

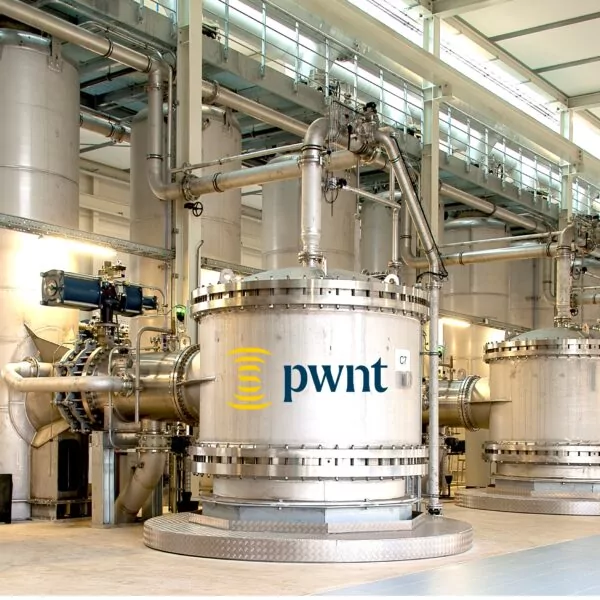

The project introduced a groundbreaking combination of technologies (SIX®, ILCA®, CeraMac®) following a pilot at Crownhill (2013–2015), addressing key challenges such as:

-

Delivering a compact, low-footprint footprint design in a constrained site

-

Removing dissolved organic carbon (DOC), pesticides, and microorganisms to meet stringent water quality standards

-

Reducing chemical usage, energy costs, and operating expenses

-

Ensuring reliable long-term operation and automatable performance

Key figures

10

CeraMac® C90

3750

m³/hour

90

MLD

24

MGD

Customer benefits

High-quality Drinking Water

The integrated treatment process consistently delivers excellent water quality. The system effectively removes harmful pathogens like Cryptosporidium and Giardia, pesticides, colour, and taste, ensuring safe and great-tasting drinking water for consumers.

Sustainability & Efficiency

The process reduces reliance on chemicals and energy, lowering the environmental footprint while maintaining high performance. Ceramic membranes are non-toxic and designed for a lifespan of over 20 years, contributing to sustainable operations.

Lower Operational and Lifecycle Costs

The compact design requires less material and construction effort, while automated operations reduce the need for staffing. The use of long-lasting ceramic membranes and reduced chemical consumption contribute to lower lifecycle and operational costs.

Robust, Future-proof Design

The fully automated, modular system ensures resilient operation under varying raw water conditions. It is adaptable to evolving regulations and built to support long-term performance with minimal maintenance.

Solution

PWNT’s integrated solution was deployed at full scale:

-

Suspended Ion Exchange (SIX®): Removes DOC, pesticides, and color-causing organics with regenerable resin.

-

Inline Coagulation (ILCA®): Targets high-molecular-weight organics, reducing coagulant usage by over 50%.

-

CeraMac® C90 Ceramic Membrane Microfiltration: 900 ceramic membranes housed in 10 vessels provide an absolute physical barrier to microorganisms.

This compact, fully automated system replaced traditional coagulation and sand filtration and now produces 90 MLD faster, with reduced chemical and energy needs, all while maintaining exceptional drinking water quality.

Contact our experts

Discover our solutions

Membrane – CeraMac®

- Drinking water

CeraMac® is an innovative and cost-effective ceramic membrane filtration solution, designed to provide high-performance, sustainability, and robustness to water treatment processes. (...)

- Municipal

Flocculation-coagulation – ILCA®

- Drinking water

In-Line Coagulation and Adsorption ILCA® is a compact in-line coagulation and adsorption process developed by PWNT to simplify and optimise pre-treatment upstream of advanced (...)