Project's context & challenges

Hampton Loade Water Treatment Works, operated by South Staffordshire Water, underwent a major upgrade to improve water quality and address risks identified by the Drinking Water Inspectorate (DWI). The site required modernization to maintain compliance with increasingly stringent regulations and to continue supplying safe drinking water to a large portion of the West Midlands region.

This project aimed to:

-

Improve protection against microbiological risks: The existing process was not consistently removing pathogens such as Clostridium perfringens and Cryptosporidium, raising concerns over the safety of the supply.

-

Address aesthetic issues in treated water: Customers had experienced incidents related to taste, odor, and discoloration, linked to insufficient removal of natural organic matter.

-

Enhance resilience under varying raw water conditions: Seasonal changes and weather events caused fluctuations in turbidity and contaminant levels, challenging the plant’s ability to deliver consistent water quality.

Key figures

20

CeraMac® C90

8750

m³/hour

210

MLD

55

MGD

Customer benefits

High-Quality Drinking Water

The physical barrier provided by CeraMac® ensures effective removal of particulates and pathogens, even under variable raw water conditions.

Sustainability & Efficiency

The membrane upgrade reduces reliance on energy-intensive coagulation and minimizes carbon footprint, supporting South Staffs Water's net-zero emissions objectives.

Lower Lifecycle Costs

PWNT’s ceramic membranes offer durable, low-maintenance filtration compared to traditional filters, reducing chemical usage and operational complexity.

Resilient, Future-Proof Design

This retrofit demonstrates the adaptability of PWNT’s technology within existing facilities, ensuring continual performance and regulatory compliance through changing water quality demands.

Solution

PWNT delivered core process innovations to support South Staffs Water in enhancing water quality and building future treatment resilience. Our scope included:

-

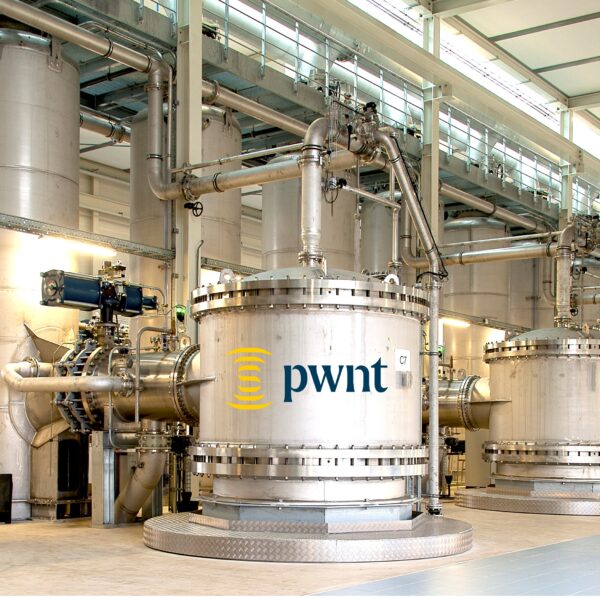

CeraMac® ceramic membrane system: 20 CeraMac® C90 vessels installed for high-performance removal of particulates and pathogens, including Cryptosporidium.

-

Design and engineering: Customized process and equipment design, enabling seamless integration with existing infrastructure.

-

Supply and commissioning: Delivery of membrane equipment and technical support throughout installation and commissioning.

The new membrane facility was implemented using a modular design, minimizing on-site construction and disruption. PWNT’s solution was integrated into the existing treatment process, following conventional clarification and coagulation steps upstream, and preceding granular activated carbon (GAC) filtration downstream, forming a robust, multi-barrier treatment approach.

Contact our experts

Discover our solutions

Membrane – CeraMac®

- Drinking water

CeraMac® is an innovative and cost-effective ceramic membrane filtration solution, designed to provide high-performance, sustainability, and robustness to water treatment processes. (...)