Project’s context & challenges

Riventa partnered with a global food manufacturer to improve performance of cooling-system pumps at one of it's production sites. The study identified major energy-saving opportunities and clear refurbishment priorities.

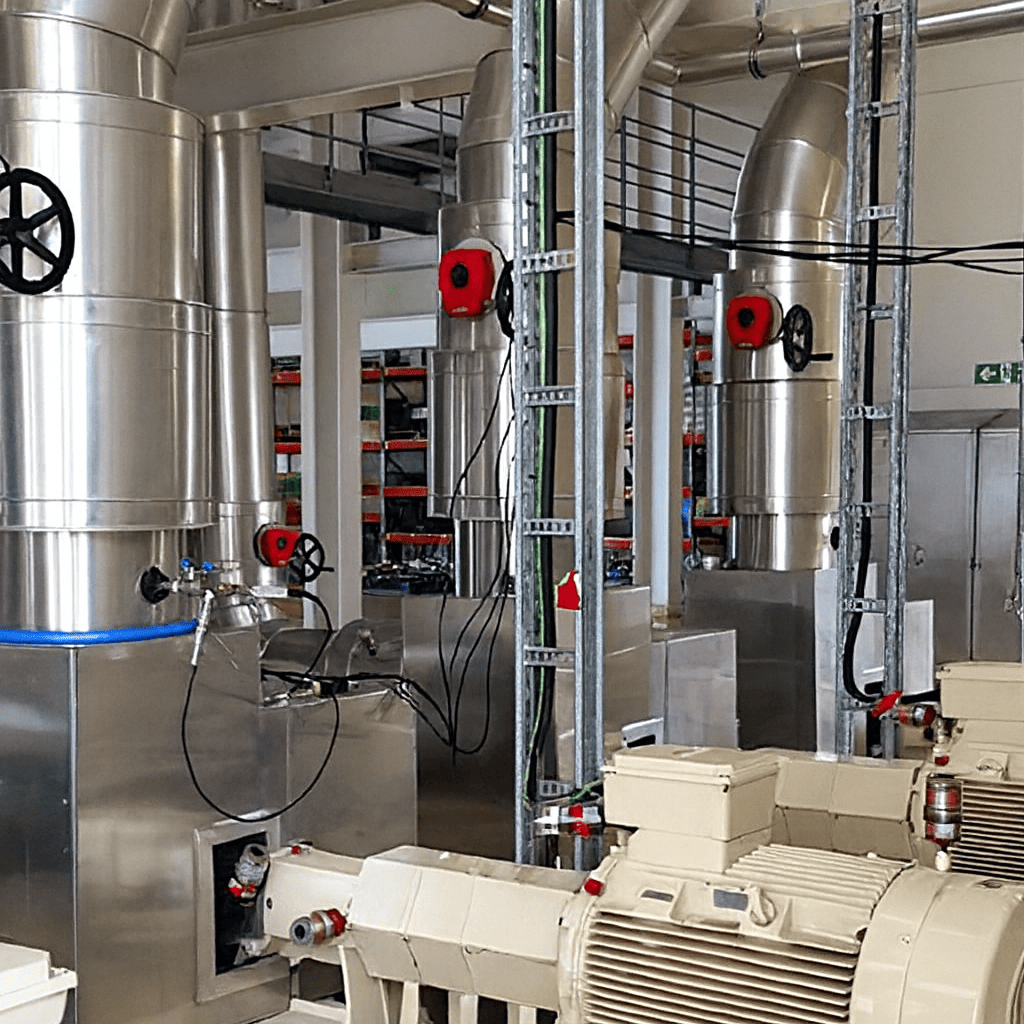

The plant's cooling system consists of:

-

Factory pumps (1-5): circulate chilled water to the factory

-

Evaporator pumps: return chilled water to refrigeration exchangers

Key figures

£181.4K (pumps 1–5)

Energy cost

Flow 26%

Above meter reading

£19,200/year

Savings via pump refurbishment

£10,600/year

Savings from pump reprioritization

75% (BEP 81%)

Efficiency

"None of the pumps we tested reached the manufacturer's BEP (81%). In fact, the maximum pump efficiency possible was found to be 75% (achieved by pumps 1&2 only) "

- Riventa case study: Food production plant -

Customer benefits

Immediate £10,600/year savings with no investment

Long-term £19,200/year potential from refurbishment

Reduced energy use and extended equipment life

Accurate data for maintenance planning

Solution

Using FREEFLOW thermodynamic testing (ISO5198), Riventa measured pump pressures, differential temperatures, and power input. Findings led to operational reprioritization and refurbishment recommendations for improved efficiency and realibility.

Scope of supply

- FREEFLOW performance testing

- SCADA data analysis

- Pump efficiency assessment and prioritization

- Refurbishment strategy and payback analysis