Project’s context & challenges

Cedrob S.A., a leading and fast-growing poultry producer in Poland, is expanding its slaughtering operations while aiming to minimize environmental impact and secure long-term water availability. Due to site development by extra slaughterlines and rendering facility as well as climate-related pressure on local groundwater resources, additional freshwater abstraction became restricted. At the same time, Cedrob sought to increase production without increasing its environmental footprint.

In partnership with Nijhuis Saur Industries, Cedrob therefore developed an integrated and sustainable water management strategy combining wastewater treatment, water reuse, and waste-to-energy. The objective was to ensure reliable internal water supply, minimize discharge and disposal, and convert organic residues into renewable energy. Today, more than 50 % of the site’s water demand is covered by reclaimed process water.

>10 000 m³/day

Wastewater treatment capacity

>5 000 m³/day

Reclaimed water production

>14 000 Nm³/day

Biogas production

Customer benefits

Robust wastewater treatment for slaughterhouse and rendering facility with safe disposal to river

Produces reclaimed water covering ~50 % of site water demand based on drinking water standards

Enables expansion without increasing environmental impact

Generates biogas from WWTP sludges for renewable energy utilization in the slaughterhouse operations

Reduces sludge disposal volumes and associated costs

Delivered as an integrated water, wastewater, reuse, and energy solution with long-term support

Service level agreement with real time monitoring and on-site presence by NSI specialists

Solution

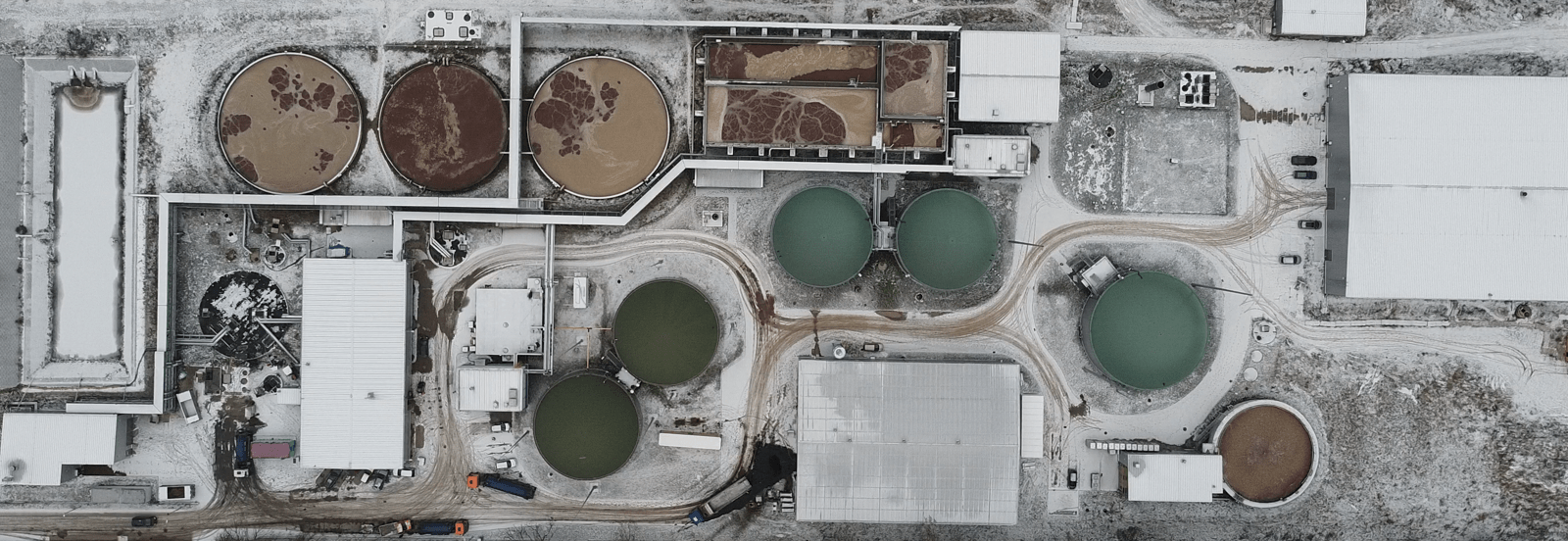

Nijhuis Saur Industries (NSI), part of Saur Group, delivered a full-scale water, wastewater treatment, water reuse, and biogas plant for Cedrob. The installation treats high-strength effluents from slaughtering and rendering processes and converts them into reclaimed process water, river discharge effluent and renewable energy.

The treatment train combines advanced primary and biological treatment with membrane-based water reclamation and anaerobic digestion. Organic residues are converted into biogas with >80 % methane content, used on site for renewable heat and energy generation. The treated effluent is further polished through ultrafiltration and reverse osmosis to produce high-quality reclaimed water suitable for internal reuse based on drinkwater standards.

Digestate is stabilized using advanced high rate nitrogen removal with anammox solution, minimizing impact on the wastewater treatment plant processing while enabling nutrient rich solid fraction to be utilized by local farmers.

Scope of supply

- Design and construction of WWTP, water reuse station, and biogas plant

- Equipment and services supply covering primary, secondary, and tertiary treatment

- Membrane-based water reclamation and disinfection

- Sludge treatment, digestate management, and resource recovery

- Electrical works, piping, automation, and commissioning

- Long-term services and mobile support solutions

Applied solutions

Primary treatment

- NTF 4×400 filtration and solids removal

- 3x IPF180 Flocculation and flotation systems

Biological treatment

- BIOCTOR-CONTINUOUS with AS-DAF polishing

- BIOCTOR-CONTINUOUS with Hybrid MBR polishing

Anaerobic digestion & sludge line

- TAURUS anaerobic digesters for biogas production

- BIOCTOR-HRNR digestate treatment (Anammox nitrogen removal)

- Decanter centrifuge dewatering

Water reclamation

- Sand filtration

- Ultrafiltration (UF)

- Reverse Osmosis (RO)

- Disinfection