Project's context and challenges

Wastewater (vapor condensate) from the digested sludge and the condensate from sludge drying, is drastically reduced in ammonium with ByoFlex® during the tourist peak periods on the island Rügen. The existing WWTP as a result can deal with increased hydraulic loadings, with reduced ammonium/ammonia concentrations. Herewith the Rügen plant is also ready for more stringent nitrogen emission levels in the future, without the need to expand the existing WWTP.

Key figures

5-7 m³/h

throughput

>85%

N-removal

Customer benefits

Chemical physical process, switch on switch off capacity

Drastically increases capacity of existing WWTP

Substitutes conventional biological nitrification/denitrification

No alkaline agent required

Small footprint

Solution

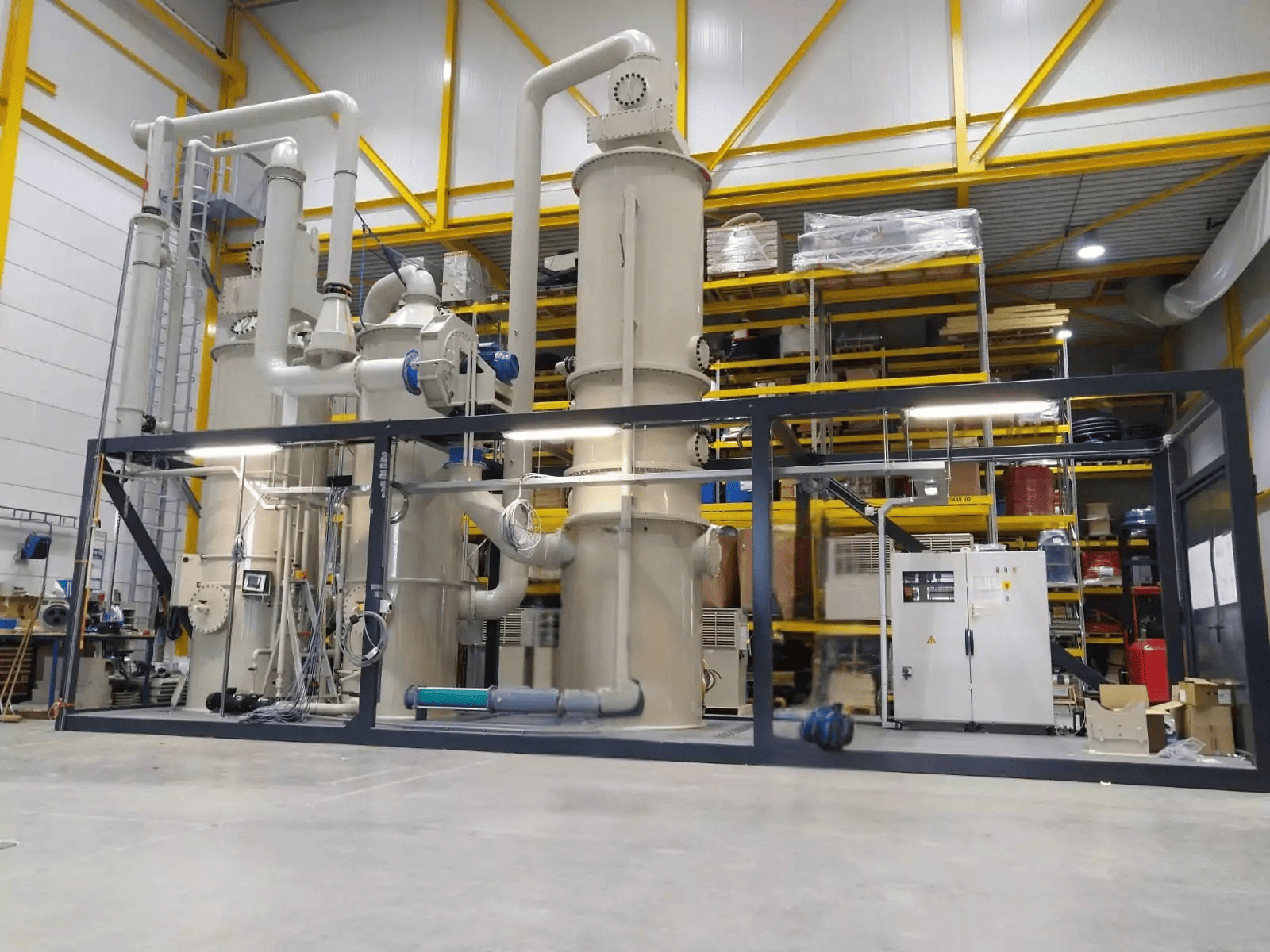

Byosis delivered and supervised the installation of the ByoFlex® 5 unit, consisting of Stripping column and 2 scrubber columns including heat exchangers with heat recovery. The system is configured to customer-specific parameters, such as the waste waters viscosity, variable throughput, dry matter content and the specific wastewater components. During the initial months of operation, Byosis ensures optimal and reliable performance by giving guidance on systems operation.

Scope of supply

- Supply of ByoFlex® 5, Heat Exchangers, CIP1500

- Installation, commissioning and project management

- Start-up and training of operators

- Operational assistance and analysis during the test period

Applied solutions

- ByoFlex® 5 Ammonia Stripper including heat exchangers

- CIP1500 (Cleaning-in-Place unit of the heat exchangers)