Project’s context & challenges

Riventa collaborated with a major South Korean water supplier to assess and optimize it's pumping assets. The project identified significant energy savings and informed refurbishment strategies across eight pumping stations.

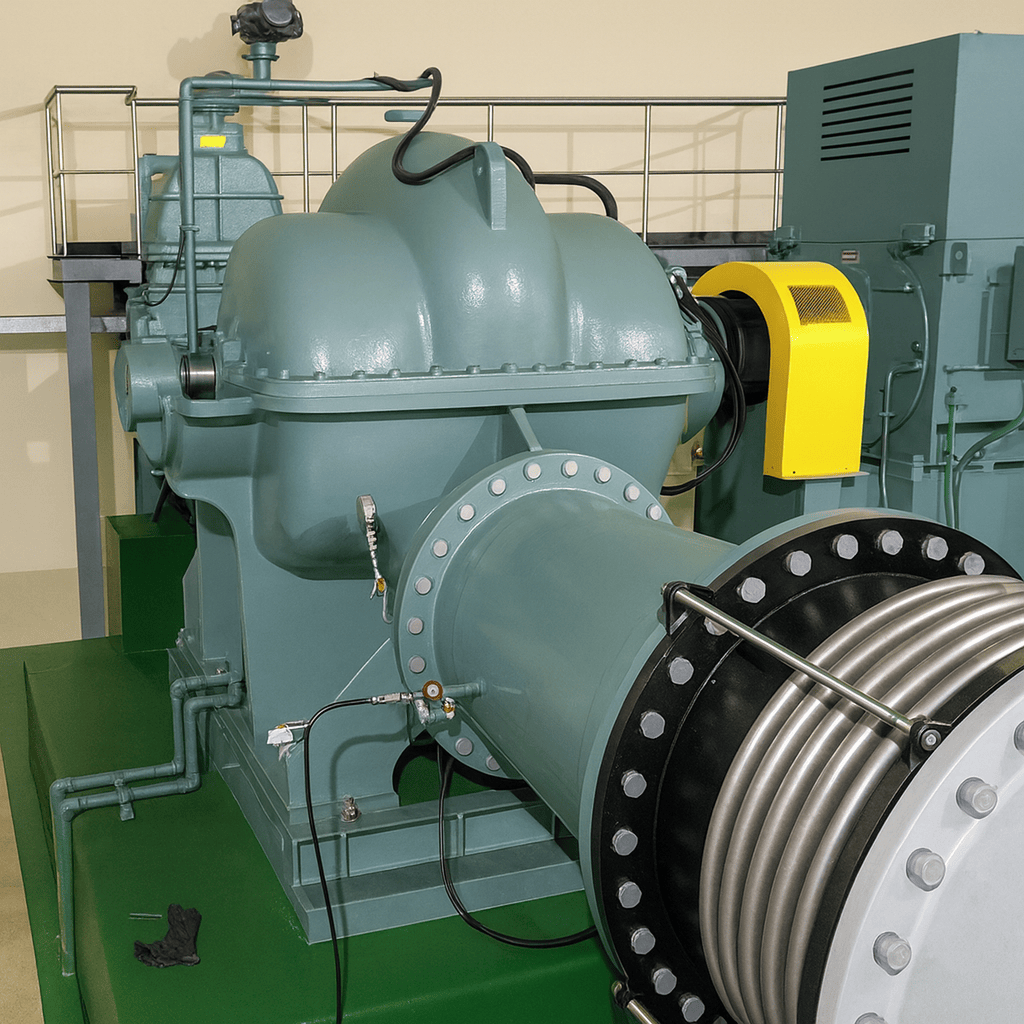

The network operates 52 pumps across 8 pumping stations, with varied configurations including fixed-speed and variable-speed units. Historic inefficiencies and oversized pumps required a data-driven diagnostic approach to improve performance and reduce costs.

Key figures

£111k/year

refurbished 3 pumps (Station S)

£85k/year

reschedule pumping (Station I)

£346k CAPEX

3-year payback

Severe cavitation

efficiency loss

"Our findings revealed significant inefficiencies and opportunities for improvements. By combining thermodynamic testing with strategic analysis, we helped the client target investments and operational changes for maximum impact. "

Customer benefits

Clear, data-driven insights into pump performance

Identified strategic refurbishment opportunities

Potential to reduce energy costs significanty

Informed decisions for long-term asset management

Solution

Riventa deployed i’s FREEFLOW portable testing technology and applied thermodynamic measurement techniques (ISO 5198) to evaluate pump efficiency, flow rates, and operating conditions. The analysis highlighted oversized pumps, cavitation issues, and scheduling inefficiencies, enabling targeted recommendations for refurbishment and operational changed.

Scope of supply

- FREEFLOW pump testing across 52 pumps

- Efficiency and performance analysis

- Identification of refurbishment priorities

- Recommendations for optimized scheduling