Project’s context & challenges

The Andijk III Water Treatment Plant was designed to treat 120 million liters of surface water per day from the IJsselmeer. The project was commissioned by PWN, the drinking water utility of North Holland, and was driven by the need for a more sustainable and effective pre-treatment system to ensure high water quality while reducing environmental impact and energy consumption.

In operation since 2014, the plant required the integration of advanced technologies to:

-

Remove a wide range of trace contaminants, including dissolved organic carbon, pharmaceuticals, and pesticides.

-

Minimize reliance on chemicals and reduce the environmental and operational footprint.

-

Ensure the system’s long-term reliability, scalability, and compatibility with existing and future infrastructure.

Key figures

6

SIX® trains

10

CeraMac® C90

120 MLD

32 MGD | 5000 m³/hour

Customer benefits

Improved water quality and safety for consumers

Our advanced multi-barrier treatment solutions safeguard public health by effectively removing turbidity, micro-pollutants, and pathogens. This ensures consistently safe, reliable drinking water that meets European quality standards. Utilities also benefit from enhanced regulatory compliance and future-proof solutions that adapt to evolving legislation and water challenges.

Environmental impact & Sustainability

Our solutions are designed to minimize environmental footprint by significantly reducing chemical consumption, which in turn lowers sludge generation and disposal needs. Optimized processes also require less energy, supporting utilities in reducing operational costs and carbon emissions. Together, these benefits contribute to more sustainable, resource-efficient water treatment operations.

Lower energy consumption & Cost efficiency

Our systems are designed for energy-efficient operation, helping utilities significantly reduce power usage compared to conventional treatment technologies. This not only lowers operational costs but also supports long-term sustainability goals.

System reliability

The plant is built on durable ceramic membranes with a lifespan of more than 20 years, combined with suspended ion exchange. Its modular system design ensures long-term performance, operational resilience, and simplified maintenance, providing consistent water quality and reduced lifecycle costs.

Solution

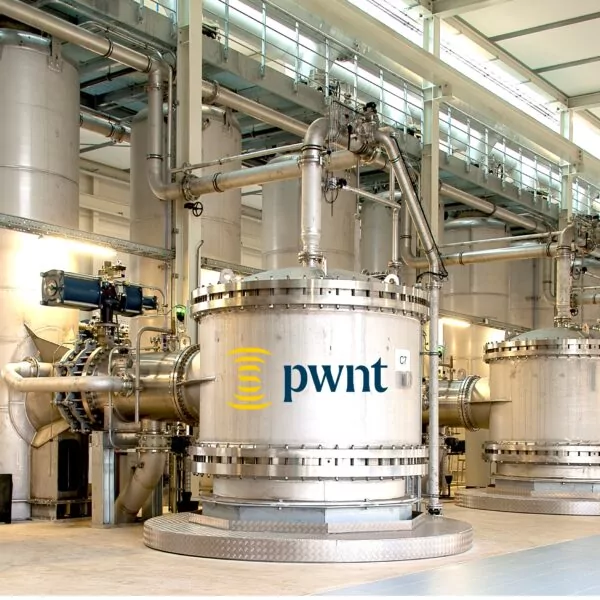

PWNT provided a sustainable, high-performance pre-treatment solution tailored to the needs of the Andijk III facility. The system integrates several advanced technologies, including suspended ion exchange (SIX®) for the removal of natural organic matter and targeted micro-pollutants, and a robust ceramic membrane filtration stage using 10 CeraMac® C90 vessels. In this application, the membranes operate without the need for chemical cleaning-in-place (CIP), further reducing chemical use and operational complexity.

Combined with the existing ultraviolet (UV/H₂O₂) and granular activated carbon (GAC) treatment steps, the result is a robust and sustainable water treatment process. The full system maximizes reliability and efficiency while delivering safe, high-quality drinking water to the region.

Contact our experts

Discover our solutions

Membrane – CeraMac®

- Drinking water

CeraMac® is an innovative and cost-effective ceramic membrane filtration solution, designed to provide high-performance, sustainability, and robustness to water treatment processes. (...)