The inclusion of chromium(VI) compounds in Annex XIV of the REACH Regulation in 2013 has led, in the years that followed, to an increasing shift toward chromium(III)-based baths in decorative electroplating. Today, the use of chromium(VI) compounds is only permitted under restricted conditions by the European Chemicals Agency (ECHA). Nevertheless, BIA Kunststoff- und Galvanotechnik GmbH & Co. KG continues to predominantly use trivalent chromium baths for decorative plating due to technical advantages of the process, such as color variability of the coating and paintability.

In order toTo minimize the additional costs associated with trivalent coating processes, BIA participated between 2020 and 2024 in the EU Horizon 2020–funded project “Intelligent Water Treatment Technologies” (intelWATT). The objective of Application Study 3 within this project was to concentrate previously unused valuable substances in wastewater from the trivalent plating process as energy-efficiently as possible, enabling their complete reuse in the trivalent production bath for chromium deposition. Full recovery of chromium from the wastewater would also eliminate the previously complex wastewater treatment required for trivalent chromium effluents.

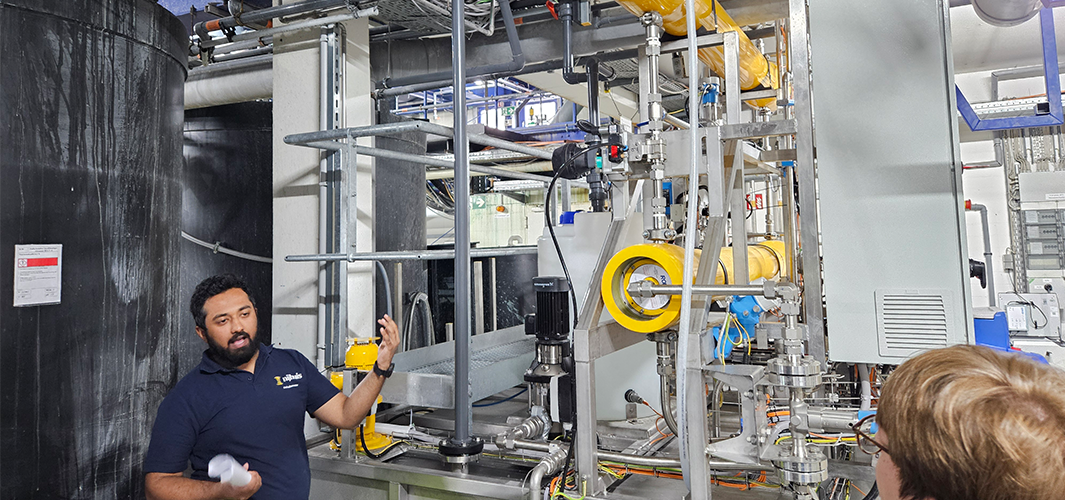

As part of the intelWATT project, a high-pressure reverse osmosis process for the energy-efficient concentration of trivalent chromium wastewater was investigated in collaboration with TH Köln and the University of Birmingham. Ultimately, a pilot plant was installed at BIA by Nijhuis Saur Industries.

Fundamentals and status quo of trivalent chromium wastewater treatment

To keep chromium stable in solution in chromium(III) electrolytes while simultaneously achieving good deposition performance, organic complexing agents are added. These compounds complicate wastewater treatment, as chromium in this stabilized form cannot be sufficiently removed from the wastewater by hydroxide precipitation as chromium hydroxide sludge. Therefore, pretreatment is required to break up the complexes and render chromium accessible for subsequent precipitation.

At BIA, this is achieved through a physicochemical pretreatment using UV radiation combined with the simultaneous addition of hydrogen peroxide. The highly reactive hydroxyl radicals formed during this process oxidize the complexing agents in the wastewater, allowing the target chromium concentration to be achieved after hydroxide precipitation. Disadvantages of this process include a comparatively high energy demand of 115 kWh per cubic meter of chromium(III) wastewater, as well as the required addition of oxidation and precipitation chemicals.

Against this background, establishing a closed-loop system for recovering valuable substances contained in chromium(III) wastewater—and thereby eliminating complex wastewater treatment—is of particular interest.

Solution approach

To identify a suitable conversion process, an analytical comparison was carried out between chromium(III)-containing rinse water and the corresponding chromium(III) electrolyte bath. This comparison revealed that the main difference was a significant excess of water in the rinse water. If the water content could therefore be reduced without altering the composition of the dissolved constituents, the rinse water could be reused as a recyclable concentrate.

To select an economical and production-neutral treatment process, the following requirements were defined:

- The process must have a specific energy consumption equal to or lower than that of the existing treatment.

- The process should only reduce the water content of the rinse water, preferably without altering the equilibrium of the dissolved components.

- The addition of chemicals or the induction of chemical reactions during treatment should be avoided.

Reverse osmosis meets all of these requirements. Reverse osmosis is an established process widely used on an industrial scale for seawater desalination in arid regions. By generating hydraulic pressure, dissolved salts are retained by a semipermeable membrane, while largely desalinated water is discharged as permeate.

In contrast to seawater desalination, the treatment implemented at BIA focuses on the concentrate, while the permeate can be discharged with significantly lower treatment and energy requirements. The objective is to retain the salts and organic additives contained in the rinse water as completely as possible in the concentrate.

To reduce energy consumption, a newly developed hybrid operating mode combining sequential semi-batch and hybrid semi-batch reverse osmosis was applied within the intelWATT program. In this approach, the system is pre-concentrated in semi-batch mode and, once a predefined switching pressure is reached, the system volume is compressed in a batch phase, allowing the maximum pressure to be reached in a shorter time. This reduces the average system pressure and thus lowers energy demand.

The determined energy consumption of the optimized pilot plant was 6.9 kWh per cubic meter, which is significantly lower than that of a highly efficient evaporation process requiring approximately 55 kWh per cubic meter.

The installed system essentially consists of two parallel high-pressure vessels—one containing two spiral-wound membrane modules and the other a freely moving piston—as well as a feed high-pressure pump, a recirculation pump, and storage tanks for rinse water, permeate, and concentrate.

The treatment process begins with the semi-batch phase. During this phase, the freely moving piston remains in its initial position, while rinse water is pumped into the high-pressure vessels and dewatered by passing through the membrane. The concentrate is simultaneously recirculated. Once the switching pressure is reached, the batch phase begins, during which piston movement reduces the volume of the concentrate. As the volume decreases, system pressure increases exponentially. When the piston reaches its end position, the batch phase ends. To discharge the concentrate, the system is depressurized, and the concentrate is displaced by rinse water into a storage tank.

Methodology

As BIA is the first electroplating company to apply reverse osmosis for electrolyte recovery, initial and process parameters related to the rinse water were only partially available or had to be derived from seawater desalination applications.

To achieve the highest possible concentration factor through reverse osmosis treatment, the pressure at the end of the batch phase needed to be close to the system’s maximum operating pressure of 115 bar. The selection of an optimal switching pressure was therefore critical, and an initial test series was conducted to determine this parameter for the rinse water to be concentrated.

With optimized switching pressure, further tests were conducted at flow rates of 6 and 9 liters per square meter of membrane area per hour. The chromium concentration in the concentrate, the chromium concentration factor, and the retention rates of individual electrolyte components were determined. The chromium concentration factor indicates how many times higher the chromium concentration in the concentrate is compared to the rinse water. Retention rates indicate the proportion of each electrolyte component retained by the membrane and thus remaining in the concentrate.

To assess the suitability of the concentrate for reuse, a concentrate sample was taken during a test at 6 liters per square meter per hour. Test coatings were produced in a Hull cell using this sample as well as mixtures with the chromium(III) production electrolyte containing 0%, 10%, and 30% concentrate by volume. The color and layer thickness of the chromium coatings were measured at defined points.

Color was measured using the Lab* method based on the CIE color space, enabling objective and reproducible color determination. Layer thickness was determined coulometrically in accordance with DIN EN ISO 2177, in which the deposited metal layer is removed electrochemically.

Results

The test series to determine the optimal switching pressure showed that at a flow rate of 6 liters per square meter per hour, a switching pressure of 60 bar allowed the system pressure at the end of the batch phase to approach the maximum operating pressure. At 9 liters per square meter per hour, the optimal switching pressure was slightly higher.

Subsequent experiments demonstrated that the concentrate contained between approximately 40% and 54% of the chromium concentration of the production electrolyte. The chromium concentration factor was higher at lower flow rates. The lower chromium concentration achieved at higher flow rates can be explained by increased membrane resistance at higher system throughput.

The results further showed consistently high retention rates for chromium(III) and sulfate, exceeding 99.5% across all tests, indicating stable and efficient separation of these ions under the tested operating conditions. In contrast, boric acid exhibited greater variability in retention, attributable to its weak dissociation and easier diffusion through the membrane. Retention of boric acid is therefore more strongly influenced by operating conditions and transport mechanisms.

Retention performance remained largely unchanged during the six-month operating period of the pilot plant, indicating stable membrane performance even over extended operating times.

To evaluate coating performance, coatings produced from the concentrate and from mixtures with the production electrolyte were assessed in terms of color and layer thickness.

At a mixture containing 10% concentrate and 90% production electrolyte, color values and layer thickness did not differ significantly from those of the pure production electrolyte. This indicates that returning concentrate equivalent to 10% of the production electrolyte volume is possible without limitations.

At concentrate volume fractions of 30% and above, a clear deterioration of coating properties was observed. This is primarily due to excessive dilution of the electrolyte by the concentrate, which is only about half as concentrated as the production electrolyte. Increasing concentrate fractions resulted in coatings that were darker, more yellowish, and thinner, limiting both decorative and technical functionality.

Overall, the results show that moderate reuse of the concentrate ensures stable process operation and consistent coating thickness and optical properties.

Conclusion and outlook

The investigations conducted with the high-pressure reverse osmosis system demonstrated that chromium(III) wastewater can be reliably concentrated to approximately 50–60% of the chromium electrolyte concentration. A loss of around 20% of the boric acid contained in the wastewater is unavoidable due to its weak dissociation and small molecular size. Nevertheless, all other components of the chromium(III) electrolyte were recovered in the concentrate at rates exceeding 99%.

Laboratory and production trials confirmed that weekly reintegration of concentrate corresponding to approximately 10% of the electrolyte volume has no significant negative effects on the color or thickness of the deposited chromium layer. The long-term effects of concentrate reuse and the durability of the reverse osmosis membranes will continue to be monitored.

Overall, high-pressure reverse osmosis represents a highly energy-efficient concentration process. Its application in the treatment of electroplating wastewater offers numerous advantages, including recovery of valuable substances, elimination of complex wastewater treatment, and energy savings. Whether the process will prove economically viable on a larger scale and be applicable to other electrolytes remains to be seen.